Bag Unloading Systems

Small Bag Unloading System

Vision offers filtered and non-filtered bagdump station units for breaking open small bags (25kg, 50Kg, etc.).If your project or product requires dust containment, the dual filter system provides greater cleanliness and productiveness for your manufacturing facility and BDS with glove box arrangement is also useful for the handling of hazardous materials in closed loop.

Our manual bag dumping stations allow for efficient dumping of small bags ... of bulk materials while effectively reducing loss of product through dusting.

Our Automatic Bag Emptying System helps in conveying, cutting and emptying of small bags in larger quantities with minimal wastage of material.

Our Bag Dumping Station comes with the dust collection system reduces the dust that is naturally generated when material is emptied from bags, boxes, drums, and other containers, into the collection hopper. This creates a more effective, efficient, and ergonomic bag dispensing system. All Stainless Steel constructed bag dumping stations.

Click on Product image to open it.

Jumbo Bag Unloading System

Our Big-Bag unloading systems are specifically designed for unloading a large variety of products from different types of Big Bags. They eliminate dust emissions, product loss or product contamination.This modular range encompasses the discharge of single or Multi-trip bags, with or without plastic liner. Also, a number of unique options are available for the safe and hygienic discharge of food ingredients, pharmaceutical products and toxic materials ... .

Features

- Big Bag Support Hopper : Designed to seat and seal the bulk bag before it is opened.- Dust Control : Two point dust collection.

- Massaging System- This assures complete emptying of the bulk bag contents without need for repositioning or adjusting the bulk bag.

- De-dusting unit- Multiple types and sizes available, attuned to the product

Click on Product image to open it.

Drum Containment System

The Drum Containment System (DCS) is a cylindrical glove box made of Stainless Steel, which comes with glass cover and two glove ports. DCS ensures precise evacuation of drums, free of contamination in a closed loop. Drum containment system is usually used where the product to be handled is hygroscopic or hazardous and needs to be evacuated dust free and spill free. Drum containment system is supported by the pneumatic conveying system to empty the drums or bags through ... vacuum, in closed loop.Features

- Glove box arrangement- In feed & out feed idler conveyor

- Inflatable Bellow

- Suction lance with lifting arrangement

- Inbuilt De Dusting System

Bag Filling Systems

Small Bag Filling System

We offer our clients with Small Bag Filling Machine which are precision engineered to fill material which are difficult to handle. This high precision weighing is coupled with a truncated pyramid table with high power vibrators. The jumbo bag filling machines can be customized, as per clients drawing and specifications. ...Features

- Before leaving the filling station the filled material is weighed desecrated & dandified Bags are stable, stackable, safe & easy to handle.- Empty bags are mounted by four loops hanging of the bulk bags on the suspended weigh frames making them easy to reach posts.

- The inlet spout is protected to the flared end of filling head by a slip ring seal which allows appropriate positioning of the liner

- Roller conveyor is also used for making it more durable.

- The SBFM can customised for any bag size or filling rate.

Click on Product image to open it.

Jumbo Bag Filling System

We are manufacturer of Big-Bag unloading systems which are specifically designed for unloading a large variety of products from different types of Big Bags. They eliminate dust emissions, product loss or product contamination. This modular range encompasses the discharge of single or Multi-trip bags, with or without plastic liner. Also, a number of unique options are available for the safe and hygienic discharge of food ingredients, pharmaceutical products and toxic materials ... .Features

- Long-lasting robust frame designed for your special bag size and application. - Fit tight spaces with a custom designed frame when you need to work around or straddle another piece of equipment or obstruction or have restricted headroom.- Manually dump smaller bags/minor ingredients with our integral bag dump station.

- Pneumatic Bag Agitation and Pneumatic side puncher Bag Agitation.

- Weighing of Big Bag during discharge.

- GMP compliant design, high quality surface.

- Integral Dust Handling.

Click on Product image to open it.

Conveying Systems

Belt Conveyor

Vision Turnkey Projects designs and manufactures Belt Conveyors to meet the needs of many industries, such as Chemical, Minerals Processing, Food, Wood Products and waste water treatment. Vision's Belt Conveyors are custom designed for your application based on proven industry standards. Bulk material characteristics, feed-rate, loading requirements and temperature are some of the parameters that we consider when designing belt ... conveyors.Features

- Dust-tight construction – To eliminate dust emissions.- High torque drive units – To power through upset conditions.

- Heavy-duty structural frames and supports – To provide system rigidity.

- Heavy-duty idlers with anti-friction bearings – To increase idler life and reduce horsepower requirements.

- Abrasion resistant belting – To reduce wear and increase life.

Click on Product image to open it.

Pneumatic Conveying System

All kinds of manufacturing industries and processes need different kinds of pneumatic conveying systems and we at Vision are proud to have the best and the widest range of these systems. Different kinds of industries need different specifications when it comes to these pneumatic conveyors and we have something to match all requirements. Our conveyor systems ... are used in industries as varied as pharmaceuticals, chemical industries, and various food industries and even in the packaging industry.Features

- Low maintenance and elevated safety.- Less spillage and dust.

- Reliability and performance by implementing highend, proven system components.

- Custom designed system solutions by our experts.

- Reliability and performance by implementing highend, proven system components.

- Transportation over long vertical and horizontal distances.

- GMP compliant design, high quality surface finishes, no dead spaces.

Click on Product image to open it.

Roller Conveyor

Our roller conveyers offer good support for the bottom surfaces of the items to be transported. These roller systems will ensure that your items will be moving smoothly along the belt. With our commitment to customer service we are driven to ensure only the top of the line product for our greatest asset, you the customer. Our qualified staff is standing by to answer any questions you may have ... .Features

- Rollers are designed for smooth rotation, low noise, and long service life.- Diameter range: 35mm to 50 mm, other diameters available on your request.

- Pipe length: 180mm to 3500 mm, other length available on your request.

- Each roller come out through strict inspection and test to ensure high level quality.

- Water proof and dust proof.

- Roller Surface Colour: Any colour as per customer request.

Click on Product image to open it.

Screw Conveyor

We design and manufacturing of screw conveyors in all configurations: vertical, inclined, plug screws, feeders, mixers, heating/cooling. We have excelled in delivering quality products and exceptional customer service ... .Features

- Heavy duty construction ex mild steel, SS304/316 or special alloys.- Customised designs to suit each application.

- Outboard bearings and packed gland / air purged shaft seals.

- Variable pitch augers to encourage mass flow.

- Half pitch augers to prevent flushing of freeflowing fluidised products.

- Double flight designs to provide even continuous discharge rates.

- Live bed multi auger designs for cohesive or easily bridging products.

Processing Equipment

Conical Blender

Conical Blender is normally used for mixing pigment, dyestuff, chemicals, battery, etc.Material can be carbon steel, manganese steel, ss304, 316L and 321; different material can also be used in parts, between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel can be sandblasting, wiredrawing, polishing, mirror polishing, glass bidding. The driven unit and power is varied according to different raw material, starting ... method, and processing.

Features

- Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.- Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.

- Full discharge and no leftover.

- No damage to fragile material.

Click on Product image to open it.

Octagonal Blender

The Octagonal/Double Cone Blender is an efficient and versatile blending machine for mixing and lubrication process of dry granuleshomogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. In Octagonal Blender the granules come from all sides due to the octagonal shape ... of the product container, hence requirement of RPM is less.Features

- Best suited for crystalline and granular type material.- Slow speed and octagonal shape gives fine blending of material.

- Good quality of blending / lubrication of granules.

- Useful for Pharmaceutical, Food, Cosmetic, Chemical products, etc.

Click on Product image to open it.

Ribbon Blender

Ribbon Blenders is designed to provide high mixing efficiency, blending small proportions into large stocks. Ribbon Blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced. Given its versatility and economy, the Ribbon Blender is often the choice for most straight forward blending requirements. Blending cycles are relatively fast and mix quality is not hard to duplicate from batch to batch. In principle, it requires very little maintenance even ... when subjected to frequent product changeovers.Features

- Efficient mixing also provides good heat transfer through optional ASME Code designed jackets.- compact and robust construction dust proof operation ensures their negligible running costs.

- Mixing vessels can be standard U-shape or cylindrical depending on internal pressure or vacuum requirements.

- We offer these in various customized sizes & finishes.

Specialized Equipment

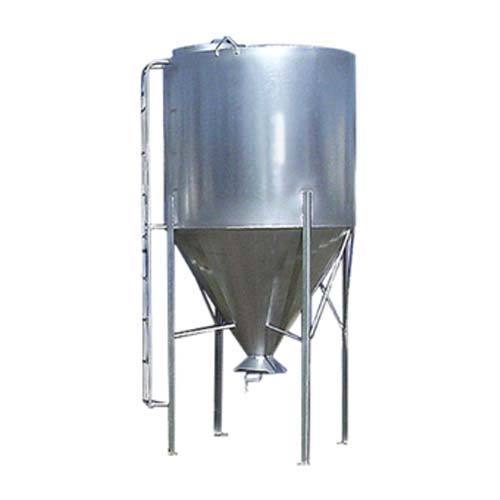

Storage Systems (Silo/Tanks/Bin)

We offer factory welded silos manufactured from steel, stainless steel. Every job is custom built per customer specifications by certified Welders. We also offer design and engineering for custom applications.Click on Product image to open it.

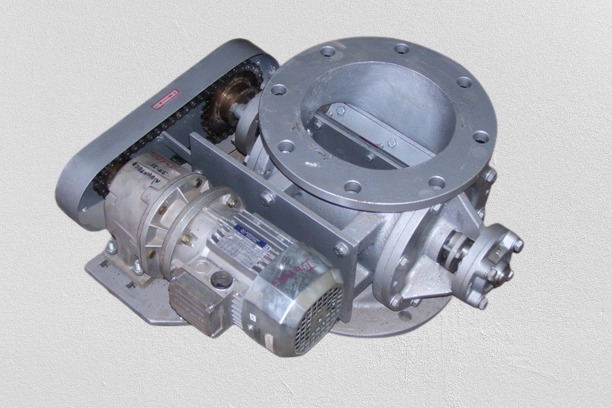

Rotary Airlock Valve

Rotary Valves are one of the most common means of feeding pneumatic conveying systems, both pressure and vacuum types. There are many other applications where they are used simply for metering of a controlled feed rate. Conveying systems with rotary valves can be turned into pressure or suction systems ... . Vision offers an extensive product range including standard rotary valves as well as hygienic valves, suitable for food and pharmaceutical industries.Click on Product image to open it.

Lump Breaker/Delumper

Our lump breakers are the perfect solution for grinding materials that tend to form lumps. The device allows breaking the lumps that form during the production or transportation process of friable materials in powder or grain ... . The fast rotation of specially shaped blades through a fixed mesh gives an efficient lump breaking action.Click on Product image to open it.

Dust Collector System

The particles released during manufacturing processes are hazardous to both worker and equipment health, quickly leading to a number of problems if particles are not captured by dust collection equipment and filtered from facility air. Dust collection addresses this problem by drawing contaminated air through a filter or separator, trapping harmful particles and releasing ... cleaner air into the atmosphere or back onto the work floor. Industrial dust collectors come in various types and sizes, including fabric filter bag houses and jet dust collectors, cartridge collectors, small dust collectors, portable dust collectors, and dust collecting systems complete with multiple suction hoods and overhanging ductwork.Click on Product image to open it.